MI Heating Units

Mineral Insulated Trace Heating Units

Through our long history and excellent reputation, TRM’s trace heating experts understand how to manufacture a solution which will last the lifetime of a project. We have designed, manufactured and installed Trace Heating Systems all around the world which have been in place now for more than 50 years and still work today.

The temperature maintenance needs can vary considerably as such a designer who can utilise the full range of Heating Units available to them as well as the experience to create an economic system which lasts the lifetime of a project will provide tangible value. TRM can provide this.

Our products are built from the ground up to perform in some of the harshest environments on Earth, from the freezing temperatures of Northern Europe to the scorching sun of the Middle Eastern deserts.

We specialise in hazardous areas and offer services in design, manufacture and installation.

The design of an appropriate heating cable or tape is important as in today’s market there is a strong emphasis on energy consumption and temperature monitoring. TRM provide a sophisticated, cloud based, control and monitoring system providing the owner with a full history of power consumption and preventive maintenance.

We manufacture our own mineral insulated cables and as such can offer total traceability in the configuration of our Heating Units to ensure the most reliable quality.

The insulation of the inner heating conductor is embedded in magnesium oxide, a non-aging and non-combustible material. A wide range of resistances ensures the termination of a multitude of heating cable lengths with various outputs and nominal voltages. We offer both single core and dual core resistance wires as well as a seamless outer jacket made from Copper, Cupro-nickel, Stainless Steel, Inconel or Alloy 825.

We have seen what can go wrong on numerous projects all over the world when the Trace Heating solution is not designed, installed or controlled properly. Why take the risk?

We have considerable experience working on Trace Heating projects in Oil, Gas, Petrochemical and Power.

However, with markets such as Concentrated Solar Power continually developing, we are constantly striving to improve our process efficiency to pass savings onto our customers.

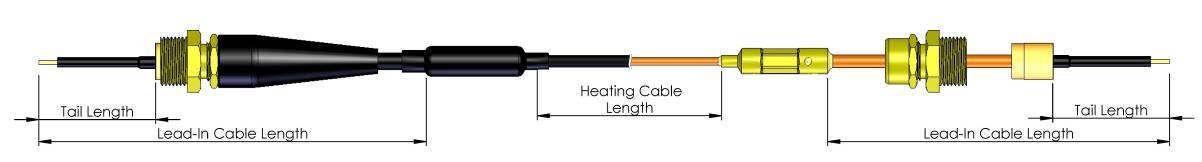

Single core MI Heating Unit Design B

Single core heating cable with Stainless Steel, Cupronickel or Nickel alloy sheath

Without earth tail

With earth tail

Single core heating cable with Copper sheath bare (right) or HDPE served (left)

Without earth tail

With earth tail

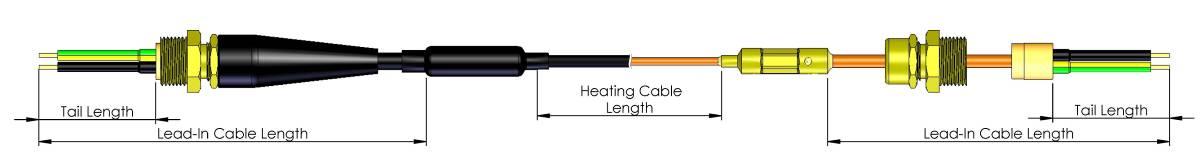

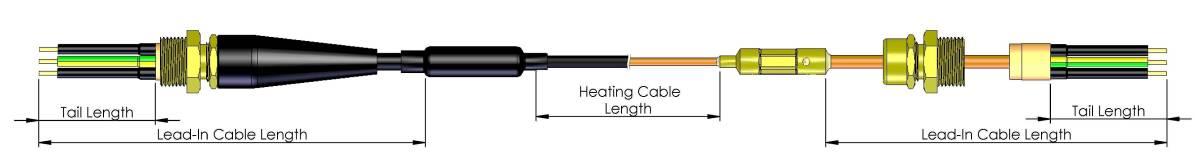

Twin core MI Heating Unit Design D

Twin core heating cable with Stainless Steel, Cupronickel or Nickel alloy sheath

Without earth tail

With earth tail

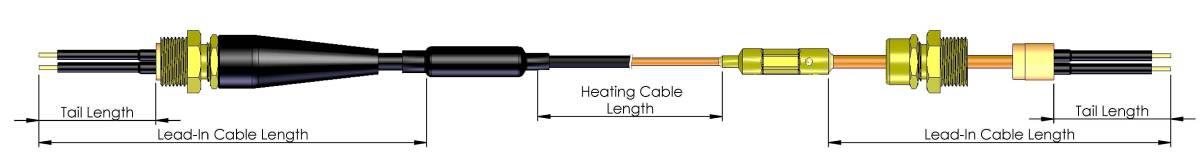

Twin core MI Heating Unit Design E

Twin core heating cable with Stainless Steel, Cupronickel or Nickel alloy sheath

Without earth tail

With earth tail

Twin core heating cable with Copper sheath bare (right) or HDPE served (left)

Without earth tail

With earth tail

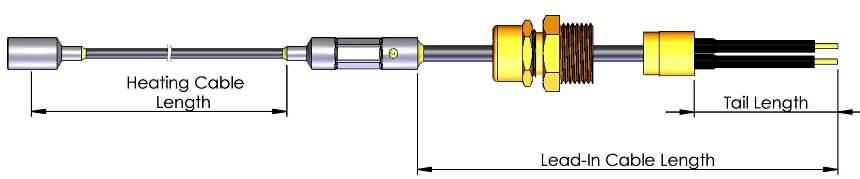

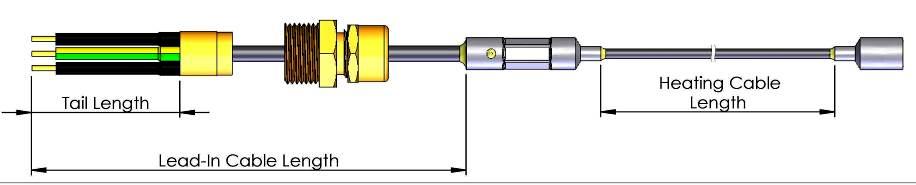

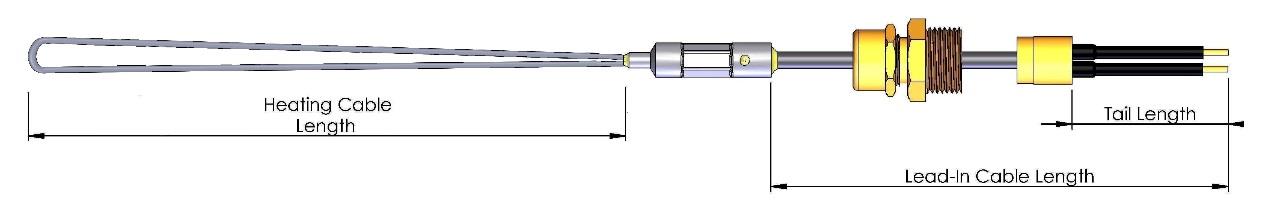

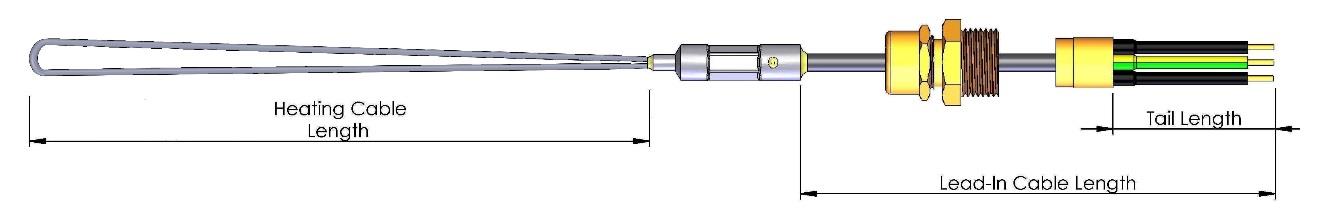

Single core MI Heating Unit Design U

Single core heating cable with Stainless Steel, Cupronickel or Nickel alloy sheath

Without earth tail

With earth tail

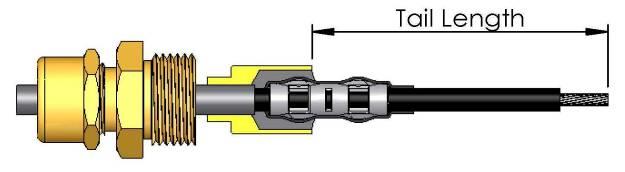

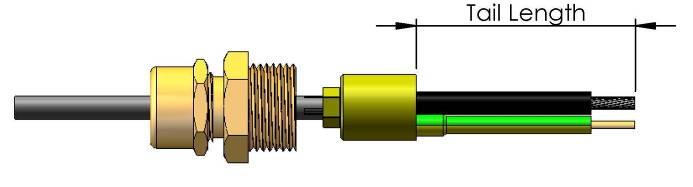

Termination Type 1 Seal

Single core cable

Twin core cable

- Seal reference

- T1

- Description

- ATEX approved seal for use in hazardous area terminations

- Conductor Type

- Flexible

- Earth tail type

- Flexible earth tag with locknut

- Pot type

- Crimp on pot

- Gland thread

- M20x1.5 Other sizes on request

- Sealant

- Epoxy resin

Standard tail lengths: 250 mm, other lengths on request

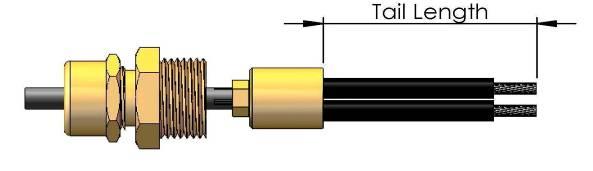

Termination Type 2 Seal

Single core cable

Twin core cable

- Seal reference

- T2

- Description

- ATEX approved seal for use in hazardous area terminations

- Conductor Type

- Solid

- Earth tail type

- Solid

- Pot type

- Braze on pot

- Gland thread

- M20x1.5 Other sizes on request

- Sealant

- TRMX compound

Standard tail lengths: 250 mm, other lengths on request

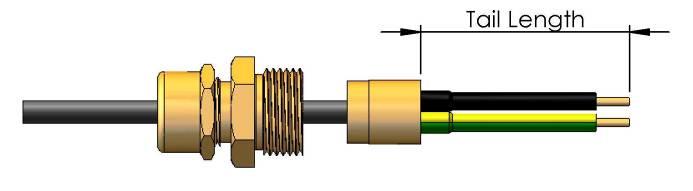

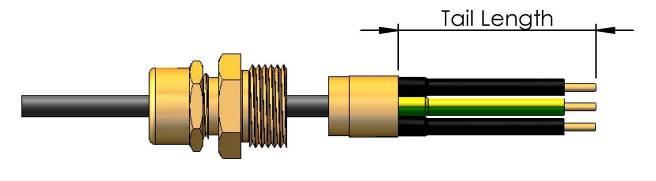

Termination Type 3 Seal

- Seal reference

- T3

- Description

- Wiring cable flexible tail seal

- Conductor Type

- Flexible

- Earth tail type

- Solid

- Pot type

- Crimp on pot with earth tail

- Gland thread

- M20x1.5 Other sizes on request

- Sealant

- Epoxy resin

Standard tail lengths: 250 mm, other lengths on request