MI Heat Trace Cable Sheath Materials

As a world-leading manufacturer of Mineral Insulated Heat Trace Cables and heat trace specialists in design, supervision and control. We have a wide range of sheath material options and can also design bespoke cables for specialist applications.

Our standard range of MI trace heating cable sheath materials are:

- Copper cable

- Cupronickel

- 321 stainless steel

- 310 stainless steel

- Incoloy 825

- Cupro nickel alloy

- Inconel 600 material

Please find a brief description of each sheath material below, our expert team are always ready to help you make sure you choose the correct material for your project, contact us here.

Stainless Steel Cable

Stainless Steel sheathed cables are designed to meet the specific needs of high-temperature capability and electrical resistance values needed for long circuit lengths. We can offer Copper, Cupronickel and Nichrome conductors.

The operating temperature is limited to 650°C. We can consult with you to understand which cable choice is best for your requirement.

Cupro-Nickel Cable

Cupronickel sheathed cables are designed to provide increased corrosion protection, especially in moist conditions. The conductor is Cupronickel allowing long lengths to be used in applications such as long line pipe tracing. It is often specified in seawater conditions due to its excellent resistance to corrosion.

The operating temperature is limited to 400°C. We can consult with you to understand which cable choice is best for your requirement.

Copper Sheathed Cable

Copper sheathed heating cables provide good heat conductivity and resistance to corrosion in most atmospheres including marine and industrial environments. It is not suitable for use with oxidising acids, halogens, sulphides and ammonia-based solutions. An HDPE outer sheath can be used to counter this, however. The conductor is copper.

The operating temperature is limited to 250°C. We can consult with you to understand which cable choice is best for your requirement.

Alloy 825 Cable

Alloy 825 sheathed heating cables are designed to meet the specific needs of high-temperature capability and electrical resistance values needed for long circuit lengths. They are ideal for industrial freeze protection and high-temperature process maintenance trace heating such as in a Concentrated Solar Power plant.

The operating temperature is up to 560°C. We can consult with you to understand which cable choice is best for your requirement.

Inconel 600 Cable

Inconel 600 is a robust material and is excellent in harsh environments due to its corrosive properties. They are typically used in bitumen plants, gas plants, oil refineries etc. where temperature, efficiency, durability and cable safety are paramount. The conductor is Stainless Steel.

The operating temperature is limited to 800°C. We can consult with you to understand which cable choice is best for your requirement.

Bespoke MI Cables

We come across many different applications and Trace Heating needs which sometimes lie outside of the Copper, Cupronickel, Stainless Steel, Inconel 600, Alloy 825 range. As needed we can manufacture and design a bespoke cable to suit your specific needs.

Please contact us here so our Design Team look at your design requirements and understand exactly what is needed.

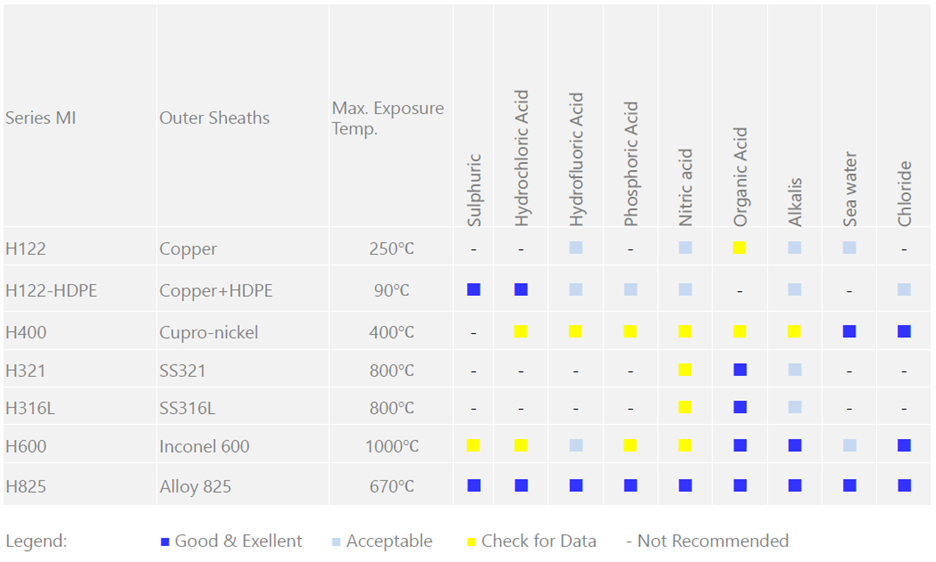

Range of Application

Our heating cables are suitable from short up to very long heating circuits. Here is an overview of our cable sheath range with suitability for max temperature and environmental conditions:

We also have a handy corrosion resistance table showing the suitability of our materials in a range of mediums, find it here.