MI Heating Cables

Mineral Insulated Heat Trace Cables

As a world-leading manufacturer of Mineral Insulated Heat Trace Cables and heat trace specialists in design, supervision and control; we pride ourselves on offering the widest possible range of heat trace cable kits and units to suit your trace heating needs.

Mineral Insulated Cable is known as the most durable electric heat trace cable in the world. It is the ideal choice when an application’s temperature and power output requirements exceed the capabilities of self-regulating and constant wattage cables and need precise temperature control. MI heating cable can be used for applications with the following requirements:

Advantages of Mineral Insulated Heat Trace Cables

- Single and dual core series heating resistance cable, magnesium oxide mineral insulated, metal sheath

- High strength

- Heating resistance cable resistance (ohms/m) determines the power output per unit length

- Output power constant, independent of temperature variations

- Maximum working voltage up to 750V

- Output power up to 300W/m (typical max)

- Highest maintain temperature up to 800 ℃

- Maximum exposure temperature up to 1000 ℃

- Hot and cold end fittings are usually prefabricated in the factory

As a leading manufacturer, we have the entire range of heating units to choose from so we can use our experience and expertise to design the most efficient system. This comprehensive range ensure a quick solution to any heating problem.

With this comes total traceability to ensure the highest quality solution. This is vital, as the composition of the cable must be able to withstand a wide range of applications including incredibly harsh conditions. TRM make all the connections and seals at the factory with advanced technology, which guarantee a consistently high level of quality of the trace heating system. Specific ranges of MI heating cables and units are approved by various hazardous and corrosive area approvals.

Cable Configuration

An MI heat trace cable kit or unit consists of the heating cable, the hot-cold joint and the cold lead cables with an appropriate seal and gland. The connecting and sealing of an MI heating unit is critical for safe and reliable operation.

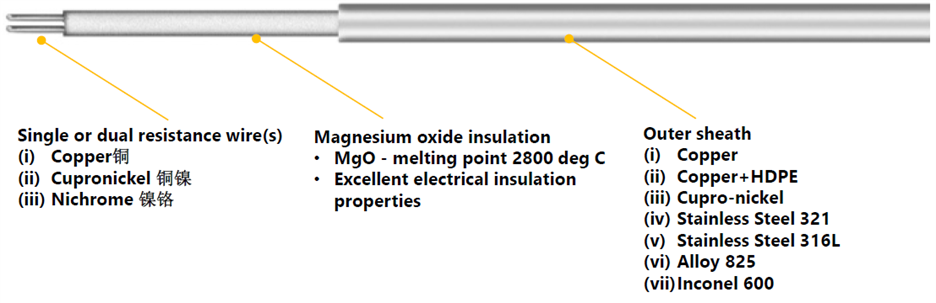

The insulation of the inner heating conductor is embedded in magnesium oxide, a non-aging and non-combustible material. A wide range of resistances ensures the termination of a multitude of heating cable lengths with various outputs and nominal voltages. We offer both single core and dual core resistance wires as well as a seamless outer jacket made from Copper, Cupro-nickel, Stainless Steel, Inconel or Alloy 825.

MICC Mineral insulated (MI) series heating systems are particularly suitable for heating applications where high power output, high exposure temperatures, or extreme resistance to environmental corrosives is needed (Alloy 825).

MI heating systems provide the most reliable solutions for temperatures of up to 1000℃.

They are your reliable solution for frost protection, temperature maintenance and generation of process temperatures up to 700℃.

Mineral insulated heating cables are suitable for heating of pipes, vessels, flanges and valves and many other applications in both hazardous and non-hazardous area applications.

Range of Application

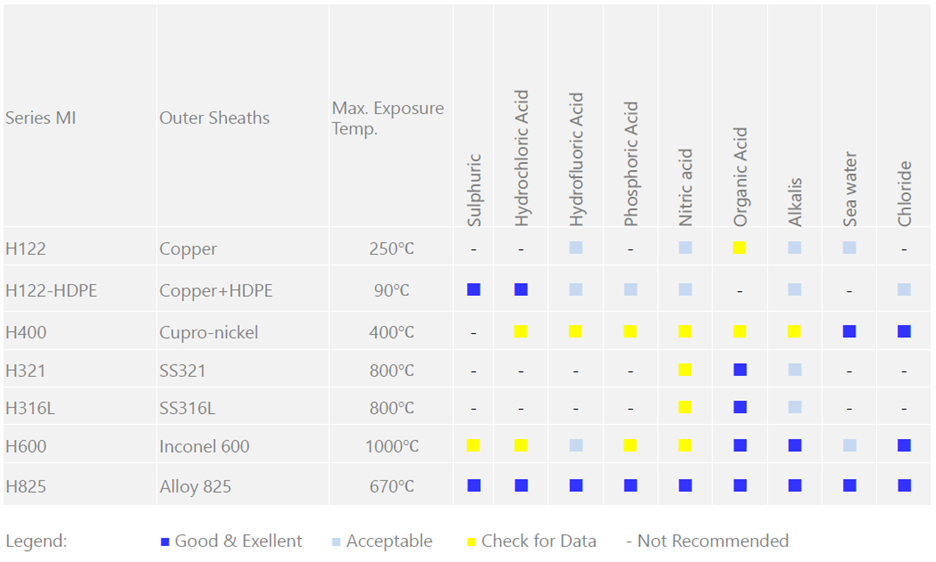

Our heating cables are suitable from short up to very long heating circuits. Here is an overview of our cable sheath range with suitability for max temperature and environmental conditions:

We also have a handy corrosion resistance table showing the suitability of our materials in a range of mediums. Find it here.

A complete range of ancillary equipment is also available. The successful completion of any heating project is entirely dependent on the original design concept based on the best interests of the client.

The design service we provide, utilises the combined benefits of an experienced team of heating engineers aided by a computerised design capability covering every aspect of industrial, commercial and domestic electric heating applications. They work closely with selected field specialists who provide the essential liaison between on the-spot problems and the expert problem solvers.

Below are the typical applications we specialise in:

- Trace Heating – Frost Protection

- Trace Heating – Process Temperature Maintenance

- Trace Heating – Hot Water Maintenance

- Maintenance

- Leak Detection Systems

- Audit and Maintenance Services