Self Regulating Heating Cables

Self Regulating / Self Limiting Heat Trace Cables

Self-regulating heating cables are useful for temperature maintenance needs at low temperatures as their power output will automatically change based on the temperature in working conditions. Self-regulating heat traces are suitable for applications such as frost protection requirements. Furthermore, it is very easy to install and can be cut to length and terminated on site. With suitable jackets, it can also be used in corrosive environments.

As SR cables are self-limiting heating cables, they reduce their output automatically when the pipe temperature is close to the desired temperature, the cable is very energy efficient, and consequently, cost-effective. At the same time, the cable can compensate for the impact of a voltage spike, losses and ambient temperature change etc.

Its highest maintenance temperature is 150°C and its highest operating temperature is 225°C.

How it works

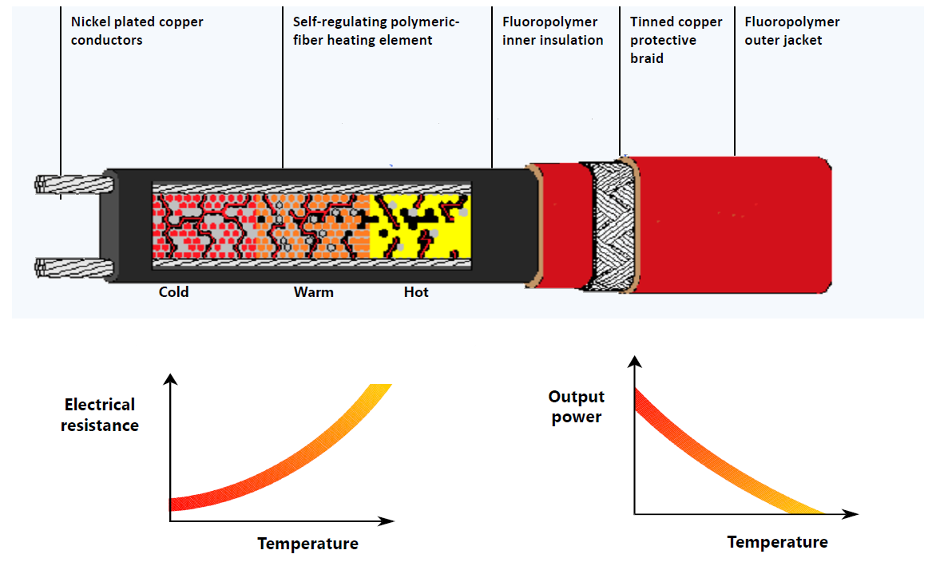

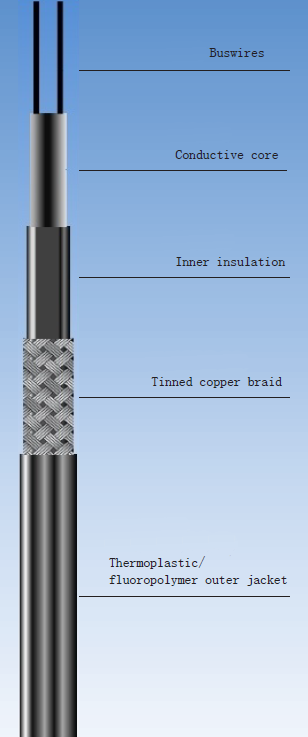

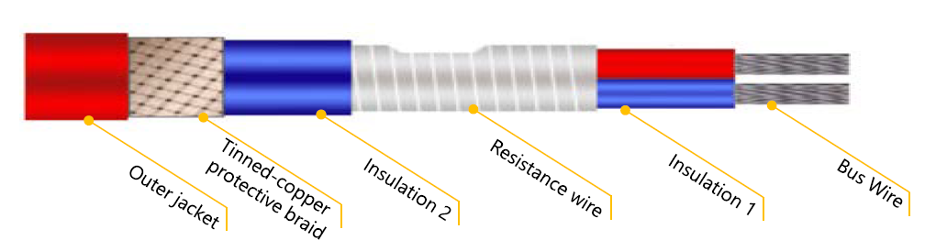

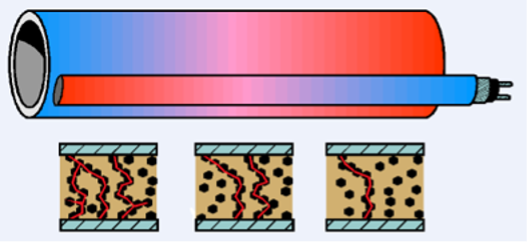

TRM’s self-regulating heating cable is constructed of a semi-conductive matrix extruded between two parallel bus wires, and an outer jacket. The semi-conductive matrix is made from conductive carbon and polyethylene. The conductive carbon forms the conductive paths between the two bus wires when powered on.

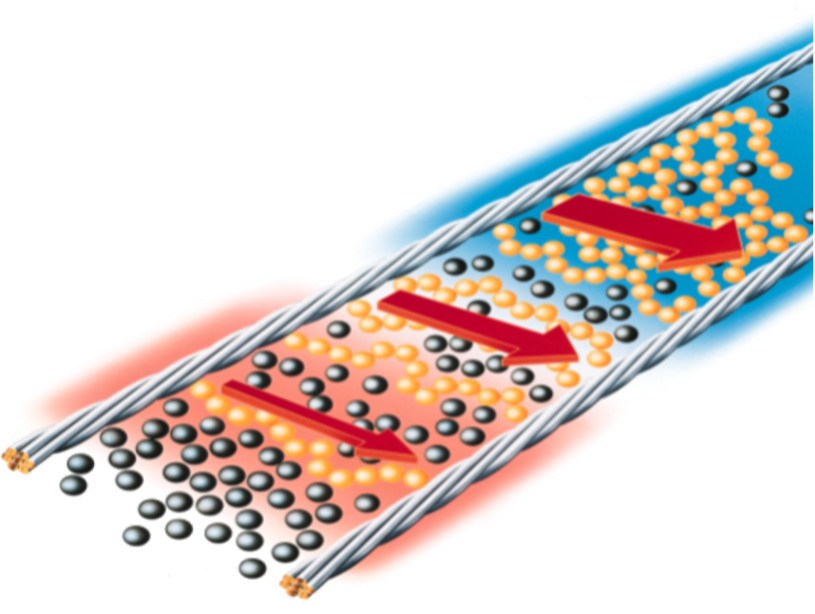

The number of the conductive paths between the bus wires varies with the surrounding temperature. TRM self-regulating heating cable adjusts its output to independently respond to temperature all along its length. When the pipe is cold, the Core contracts increasing the number of electrical paths through the conductive carbon and thereby reducing electrical resistance. The increased current flow through the core generates heat. As temperature increases, the core expands and reduces the number of electrical paths.

As core resistance is increased, heat output is reduced. As the surrounding temperature decreases, the core-structure contracts again, increasing the number of electrical paths through the conductive carbon and reducing electrical resistance which in turn produces additional heat. TRM’s self-regulating heating cables provide uniform temperature as they can regulate their output automatically.

The cable produces more heat. Compared with other heating cables, TRM’s self-regulating heating cable provides uniform temperature as it can regulate its output automatically. Of course, the performance of any system always comes down to the correct self-regulating heat trace cable installation process.

Resistance Heating Cables

Nominal voltage: 500V

Nominal power output: Rated at up to 40 W/m

Min. bending radius: 20mm

Nominal temp: 260 deC

Min. installation Temp: -50 deC

Moisture protected: Yes

Advantages of resistance heating cables

- Factory terminated

- High chemical and mechanical resistance

- Can be used in all industrial areas

- High operation temperature

- Easy to install, even on complex shapes

- Highly flexible

- Resistant to steam purging

- Maximum exposure temperature (power on/off): 260 degC

- Nominal power output: Rated at up to 35W/m and 1000 VAC

Approved for use in non-hazardous and hazardous areas. Please contact us for more information.

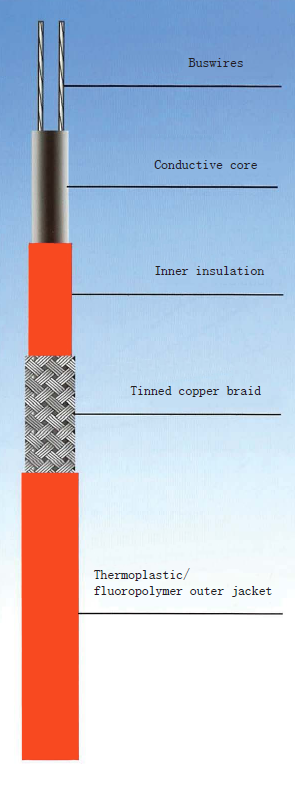

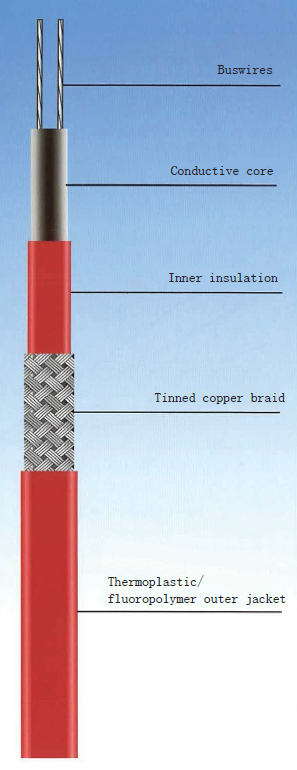

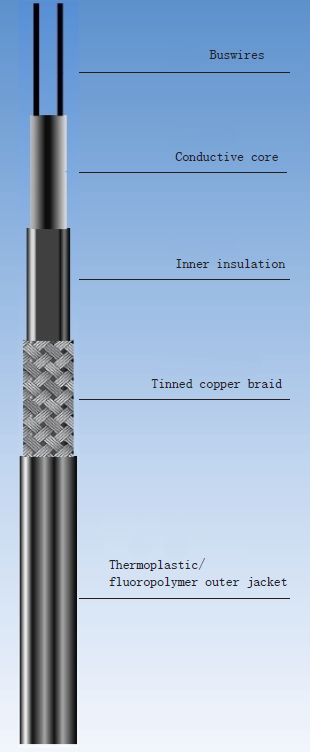

Self Regulating Cable Construction

At low temperatures, there are many conductive paths, allowing current to flow between the bus wires.

At high temperatures, the polymer expands, reducing the number of conductive paths, and thus reducing current flow.

The below diagram highlights the Self Regulating cable’s construction.

Conductive Polymers in Action and Technology

The below diagram shows the Conductive Polymers in action. As the pipe temperature increases the power output decreases. Please contact us for more information.

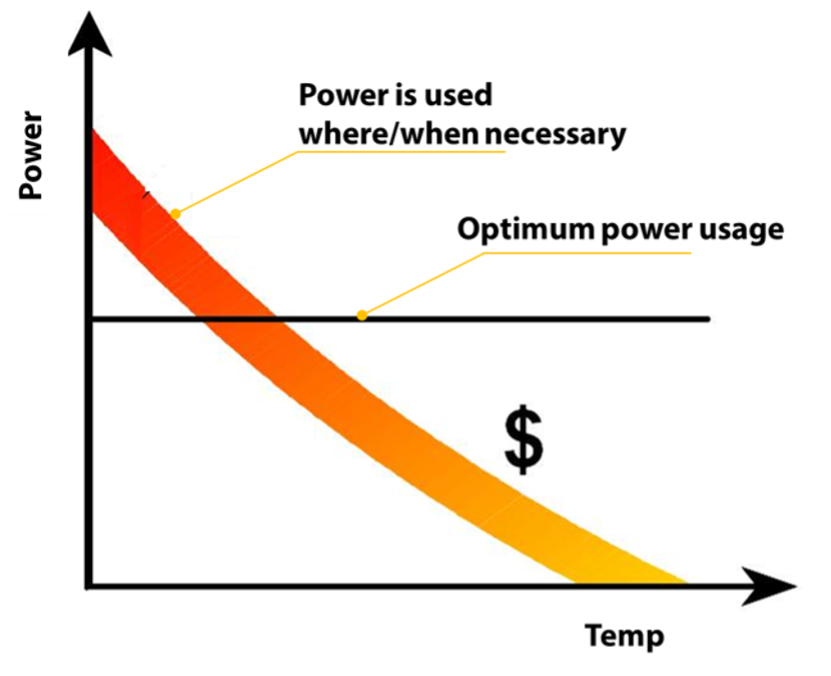

Power Output Varies With Temperature

As pipe temperature increases, power output decreases.

The correct amount of heat has to be supplied to the pipe

Cold sections of the pipe get more heat input

Warm sections of the pipe get less heat input

As shown below the Conductive Polymers change automatically. As such the cold sections of the pipe get more heat input and the warm sections of the pipe get less heat input.

Advantages Of SR Heat-Tracing Cables

- Output power changes with temperature

- Will not overheat and damage

- Overlapping cable is possible

- Parallel conducting paths

- Can be cut to length and terminated on site

- According to need can use a two-way or three-way connection

- Corrosion-resistant jacket

- Can be used at 120 volts, 208-277 volts

- Highest maintain temperature up to 150 degC

- Maximum exposure temperature up to 250 degC

- Can be used to heat plastic pipes

- Approved for use in non-hazardous and hazardous areas

Please contact us for more information.

TSRL Self-Regulating Heating Cable

TSRL Self-Regulating heating cable can be used for frost protection or temperature maintenance of pipework and vessels. Its highest maintenance temperature is 65°C, while the maximum permissible exposure temperature is 85°C. It can be cut to length on-site to match exact piping lengths and is useful in complicated piping design.

An over jacket can be provided to survive in some corrosive environments. We can consult with you to understand which cable choice is best for your requirement.

TSRW Self-Regulating Heating Cable

TSRW Self-Regulating heating cable can be used for frost protection or temperature maintenance of pipework and vessels. Its highest maintenance temperature is 110°C, while the maximum permissible exposure temperature is 135°C. It can be cut to length on-site to match exact piping lengths and is useful in complicated piping design.

An over jacket can be provided to survive in some corrosive environments. We can consult with you to understand which cable choice is best for your requirement. Please contact us for more information.

TSRH Self-Regulating Heating Cable

TSRH Self-Regulating heating cable can be used for frost protection or temperature maintenance of pipework and vessels. Its highest maintenance temperature is 150°C, with a continuous exposure temperature limit of 225°C. It can be cut to length on-site to match exact piping lengths and is useful in complicated piping design.

An over jacket can be provided to survive in some corrosive environments. We can consult with you to understand which cable choice is best for your requirement.

TSRR Self-Regulating Heating Cable

TSRR Self-Regulating heating cable can be used for frost protection or temperature maintenance of pipework and vessels. Its highest maintenance temperature is 65°C, while the maximum permissible exposure temperature is 85°C. It can be cut to length on-site to match exact piping lengths and is useful in complicated piping design.

An over jacket can be provided to survive in some corrosive environments. We can consult with you to understand which cable choice is best for your requirement. Please contact us for more information.

Parallel Constant Wattage Cables

Parallel self regulating heating cable

Nickel-chromium alloy wire contacts bus wires at regular intervals

Parallel connection to each heating zone

Nichrome wire diameter determines the output power per unit length

Output power constant, independent of temperature changes

Advantages of parallel constant wattage cables

- Parallel bus wires so it is fault-tolerant

- Can be cut to length on site

- Can not overlap or spiral wrap

- Highest maintain temperature 174 degC

- Maximum exposure temperature 200 degC

- Starting current = operating current, so no need to consider the instantaneous starting current

- Output power and high precision

- Corrosion-resistant jacket

Operating voltage 120 volts, 208-277 volts and 480 volts. Please contact us for more information.

ELK Series Resistance Cable

ELK-PTFE series constant wattage heating cable is suitable for the heating of piping and containers in industrial applications.

Further features are its high level of flexibility when laying, high chemical resistance thanks to its PTFE insulation and high mechanical loading capacity through a thick PTFE Jacket. And it can be cut in length in the field. It can also be used for longline pipes and the working voltage can be up to 1000V. It is approved for use in corrosive and hazardous areas.

The maximum working temperature is up to 180°C and can withstand routine steam purges and temperature exposure to 260°C and power off. We can consult with you to understand which cable choice is best for your requirement.