A thermistor is an element that senses temperature and is made up of sintered semiconductor material which displays a big change in resistance in proportion to a small alteration in temperature. They normally have negative temperature coefficients meaning the resistance goes down as the temperature goes up.

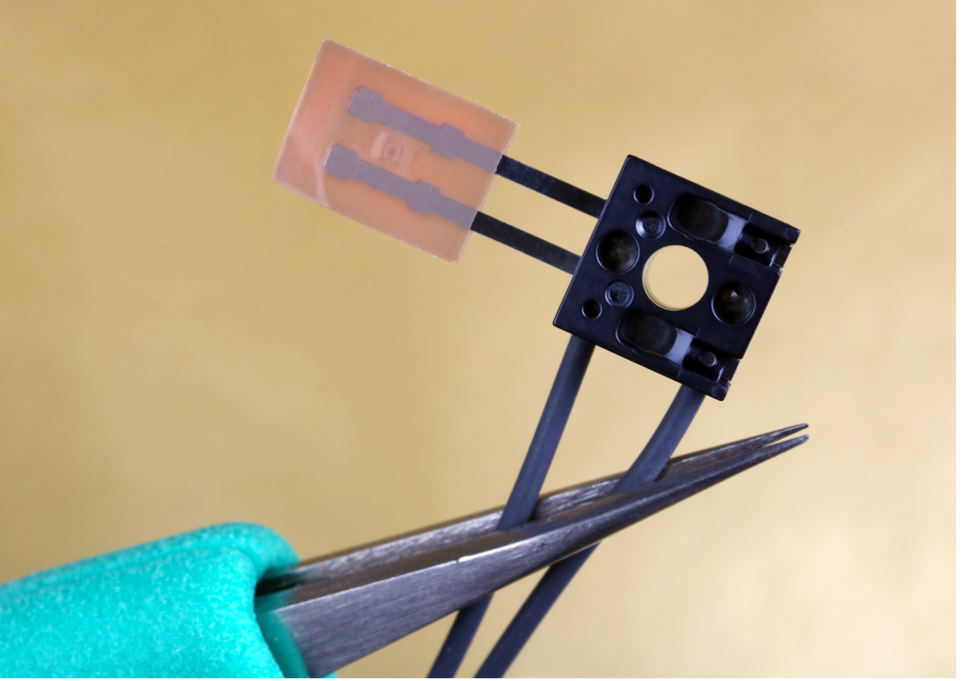

Thermistors are constructed using a combination of metals and metal oxide materials. Once they are mixed, the materials are formed and pushed into the required shape. They can then be used naturally as disk-style thermistors without any changes needed. Alternatively, they can be further shaped and put together with lead wires and coatings to create bead-style elements.

How do thermistors compare to RTDs?

Whilst RTDs change resistance in an almost linear way, thermistors have a very non-linear change in resistance and reduce their resistance as temperature increases. They continue to be a popular way of measuring temperature for several reasons including:

- Their increased resistance change per degree of temperature offers better resolution

- There is a high level of repeatability and stability

- Impressive interchangeability

- Their small size means they can respond faster to changes in temperature

Thermistors typically have two types of coatings: epoxy for use in lower temperatures (-50 to 150C) and glass coatings for higher temperature applications (-50 to 300C). These coatings are used mechanically to protect the bead and wire connections whilst offering a degree of protection from corrosion and/or corrosion too. A very small diameter and solid copper or copper alloy wires are normally supplied with thermistors. In most cases, these wires are tinned to allow for easy soldering.

Base resistance

NTC thermistors decrease in resistance with increased temperatures. This is also the case for how much resistance change per degree it will provide. For quite low temperature applications (-55 to around 70C) lower resistance thermistors are generally used. Higher resistance thermistors are used for higher temperature applications in order to optimise the resistance change per degree at the temperature that is needed. These elements are available in a range of resistances and “curves” and resistances are typically specified at 25C.

How does a thermistor work?

Unlike RTDs and thermocouples, thermistors don’t have standards linked with their resistance versus temperature characteristics or curves. As a result, there are several different ones you can choose from. Each material will offer a different resistance vs temperature “curve”. Certain materials will have better stability whilst others have higher resistances so they can be made into bigger or smaller thermistors.

What thermistor is right for your application?

Whether you are replacing a thermistor or getting one for a completely new application, there are three key things you will need to consider in order to achieve the best result. These are:

- For new applications, select proper base resistance or correctly specify the base resistance of the one that you are replacing.

- When specifying resistance-temperature correlation, make sure to be precise. For replacements, have info on existing thermistor ready

- Packaging style and size

Thermistor accuracy

Thermistors are one of the most precise temperature sensors on the market. However, they can be quite restricted in terms of their temperature range, operating across a range of 0 to 100C. If you don’t think a thermistor will be right for your normal thermocouple applications, stick with your thermocouple. Despite having a number of useful benefits, such as being chemically stable and so not massively susceptible to aging, a thermistor isn’t the right fit for every industry or process because of the limited parameters.

Size or sensor package style

When the user has determined the right resistance and curve, they should consider how they intend to use the thermistor. So, when they are choosing the right size or packaging for the sensor, it’s important to remember that in the same way as any other sensor, a thermistor will only measure its own temperature.

Thermistors cannot be submerged in a process. They are small and quickly react to temperature changes since they are only separated from the environment by a thin epoxy layer. However, you can get different styles of thermistors for different uses.

General purpose

General purpose designs can be work in a broad range of applications. From electronic equipment to structures, processes and design, and reliability testing uses, sensors of this style are easy to fit and monitor over time.

Liquid immersion measurement

Thermistors need to be protected from corrosion when they are exposed to liquids as well be carefully positioned in the fluid so it will arrive at the required temperature. This is normally done using closed ended tubes and housing that are specifically designed for the job. You need to take care and ensure that there is a clear thermal path to the thermistor and that thermal mass is as small as it can be.

How can TRM help?

At TRM, our team provide engineered solutions that perform at the highest temperatures and in the harshest environments. We are specialists in all thing’s temperature measurement, trace heating, and fireproof wiring, offering a range of useful products like MI thermocouple cable to ensure our customers get the solutions they need in their business operations. Contact us today to discuss your specific requirements and what we can do for you.