The Regulatory Reform (or Fire Safety) Order 2005 states that where it is necessary (whether it’s because of the features of the building, the activity that is completed there, any present hazards, or any other relevant circumstances) it is legally required that a responsible person must make sure the premises are, to the suitable extent, equipped with working fire detectors and alarms, to ensure the safety of all relevant individuals on the premises.

Subsection three of the order says that the chosen person to implement and maintain these measures must be competent. However, a responsible person (or someone appointed by the responsible individual) can conduct testing of the fire alarm system after being trained to do so properly.

What are the different types of fire alarm systems?

There are two main types of fire alarms for commercial buildings, manual and automatic.

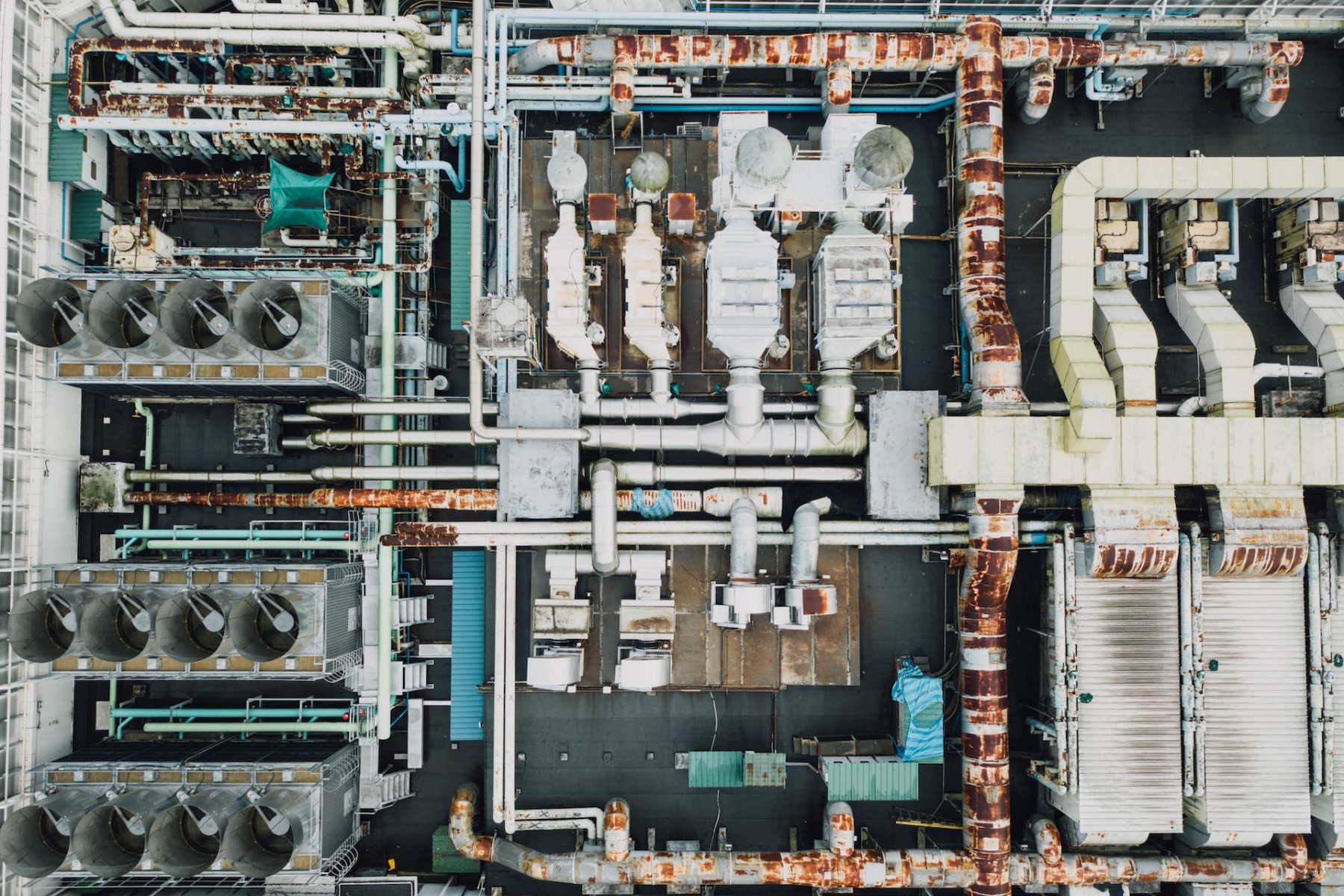

The manual fire alarm system needs someone to activate the alarm by a manual call point (outstation), which will register on the panel of the fire alarm. Outstations need to be situated on escape routes and fire exits, with extra outstations in areas at greater risk like commercial kitchens, laundries, and plant rooms.

An automatic fire alarm system is automatically activated by either detecting heat or a certain amount of smoke. It will also have the ability for a user to manually start the alarm near an outstation, which will register on the master station.

Fire alarm systems within commercial or business premises can come in two variants, conventional or addressable. A conventional system will see a detected fire (whether via an automatic detection system or manual activation at a call point) registered on the fire alarm control panel in one of the highlighted zones, for example, the ground floor, warehouse, or plant room, depending on how the system was designed and installed.

An addressable fire alarm system, where a fire is detected and registered on the control panel as a specific location or address within a zone. For example, through an automatic smoke detector in a boiler room on the ground floor, or a manual call point by the rear fire exit.

The type of fire alarm system you need for your premises should be determined and recorded in a current fire risk assessment. Also, to help reduce the risk of a fire in your premises, you should ensure you have fire resistant cable.

How often should a fire alarm be tested?

In section 25.2 of the relevant British Standard regarding testing fire alarm systems confirms that all fire alarm systems in commercial buildings are required to be tested weekly. This is to ensure that there hasn’t been any significant failure and the system is fully in working order.

To test the system, firstly you should create a list of all outstations within the premises as each one will need to be tested in a rotational order, making sure all locations are regularly tested. In smaller buildings, it’s acceptable to test only one location each week.

For instance, in a premises where there aren’t many outstations, they could all be tested over a period of two months in rotational order. In bigger commercial businesses, it might be more suitable to test two or three outstations each week, to guarantee all devices are tested over the same length of time. In the event of a fire in your building, fire proof cable can help buy you more time to ensure everyone gets out safely and there is less damage and downtime to your operations.

Do I need to be trained to test fire alarms?

Section 25.1 says that testing a fire alarm doesn’t need any specialist knowledge and can normally be conducted fairly easily. However, it might be preferable for a competent person to offer initial instruction in testing the system in order for this to be diligently carried out in the future.

The British Standard also states that fire alarm testing can usually be carried out by the occupier of the building. This could be the responsible person, or someone assigned by the responsible person, like a property manager. However, both will need basic instructions in how to do correctly do so.

Summary

Generally speaking, fire alarm systems should be tested on a weekly basis in commercial properties. As well as regularly testing your fire alarm, there are many things you can do to make sure your premises is as safe from fire as possible, including having fire retardant cable.

At TRM, we provide engineered solutions and products that help many industries with their temperature measurement, trace heating, and fireproof wiring with high quality fire cable. Contact us today to see how we can help your business operations.