Instrumentation and metrology are two terms that often get confused in some ways as they both relate to measuring. In this article, we’ll be clarifying the difference between instrumentation and metrology as well as defining each one and their role within industrial temperature measurement.

What is instrumentation?

Instrumentation is a fairly broad and general term used to describe the hardware that is used for measurement and control and can include software too. The English word “control” often includes regulation as well whilst other languages typically differentiate between manual control such as opening and closing a valve, and automatic regulation, like closed loop control. Therefore, when we consider “instrumentation” it might include valves, manometers, level indicators, and PLC controls.

What is metrology?

Metrology is the science of measurement and how it’s applied. By contrast to instrumentation, metrology is not just about the physical and routine making of measurements, it is more about the infrastructure in place that ensures we are confident in the accuracy of the measurement. It establishes a basic understanding of units and measurement processes that are essential to human activity.

Metrology details the accuracy, precision, and repeatability of a measurement. It includes traceability or comparison with a “standard” or between different measuring systems. Also, it involves all the theoretical and practical aspects of measurement, no matter the measurement uncertainty or the field of application.

What is the difference between instrumentation and metrology?

To understand the difference between instrumentation and metrology, if you consider that philosophy is ‘thinking about thinking’ then metrology is essentially ‘measuring measurement’. So, a lot of people can use and carry out instrumentation but not as many people do metrology. Both are important aspects of high temperature measurement to ensure it is done effectively, safely, and accurately.

Who are TRM?

Thermal Resources Management (TRM) provide engineered solutions and industrial heating elements that perform effectively at the highest temperatures and in the harshest environments. Our team is committed to providing tailored turn-key solutions in various applications including:

- Electric trace heating- we can design, manufacture, install/train, and control entire heat tracing systems to make up for heat losses in various areas.

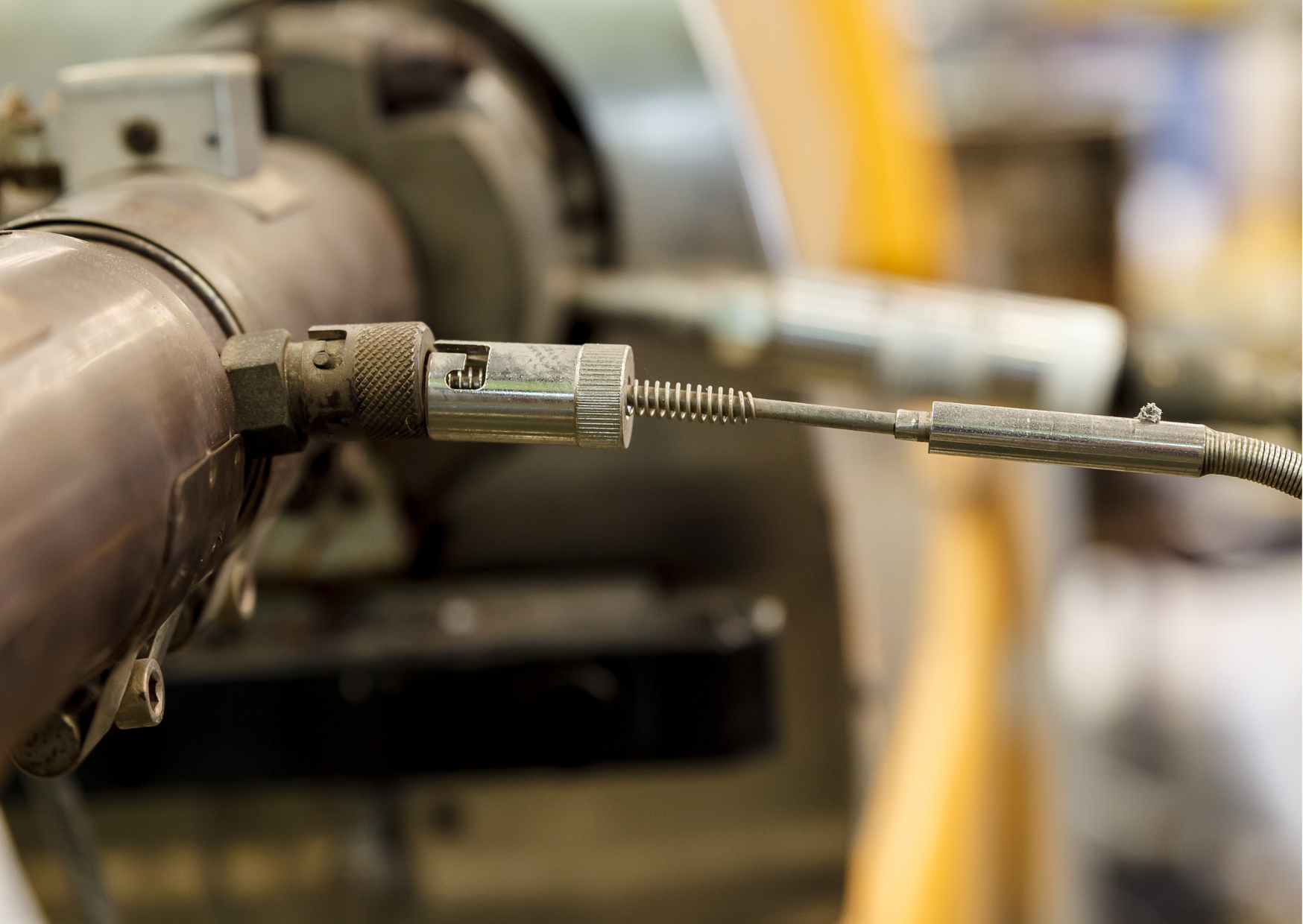

- Temperature measurement- industrial thermocouples and temperature measurement sensors can measure temperatures of up to 2300C! They are used in a broad range of applications and industries from pipelines to steel foundries and hazardous areas like Nuclear Power Station reactors and boilers.

- Fire survival wiring- the only authentic fire survival cable on the market, guaranteeing more than 3 hours of escape time in the most severe of fires. We can provide heavy duty and light duty cables in both copper and alloy 825, depending on your requirements.

Our R&D and engineering team are on hand to work with you on bespoke, innovative solutions to your project challenges. We operate in a wide range of commercial and industrial sectors such as oil and gas, petrochemical, pharmaceutical, food and beverage, chemical, and many more. To find out how we can help you with your temperature management, contact our professional team today and get on the path to cost savings and more efficient processes.